Buildings made of lightweight structures are the basis of modern business

The technology for the construction of prefabricated frame buildings from LSTK has long been popular in many countries. It is seen as a logical development of the panel housing boom in Canada, Finland, France, the USA and the USSR. Initially, modular buildings were built only for industrial, commercial and military purposes. However, the growth in demand of private buildings has led to the emergence of modular residential buildings of several varieties and functionality. Due to the strength of the elements, combined with elasticity, a high resistance to seasonal floods, mud flows and earthquakes results. These properties have made such structures popular in difficult areas in terms of soil structure and topography. Today, with the help of LSTK, 90% of structures are built for such purposes as:

commercial and industrial premises;

children's, medical and administrative buildings;

mobile modular buildings for business.

In Ukraine, prefabricated modular buildings are only gaining popularity, especially in the hotel and construction business. During the Soviet period, steel was an inaccessible material, so buying a modular building was only a dream. Now technologies and materials allow to revive the production of modular buildings at an affordable price. Promising areas are modular and not only private kindergartens, mini-offices, mobile car washes, seasonal houses (dacha cooperatives, recreation centers) and warehouse complexes.

Production of modular buildings: materials, terms and features of installation

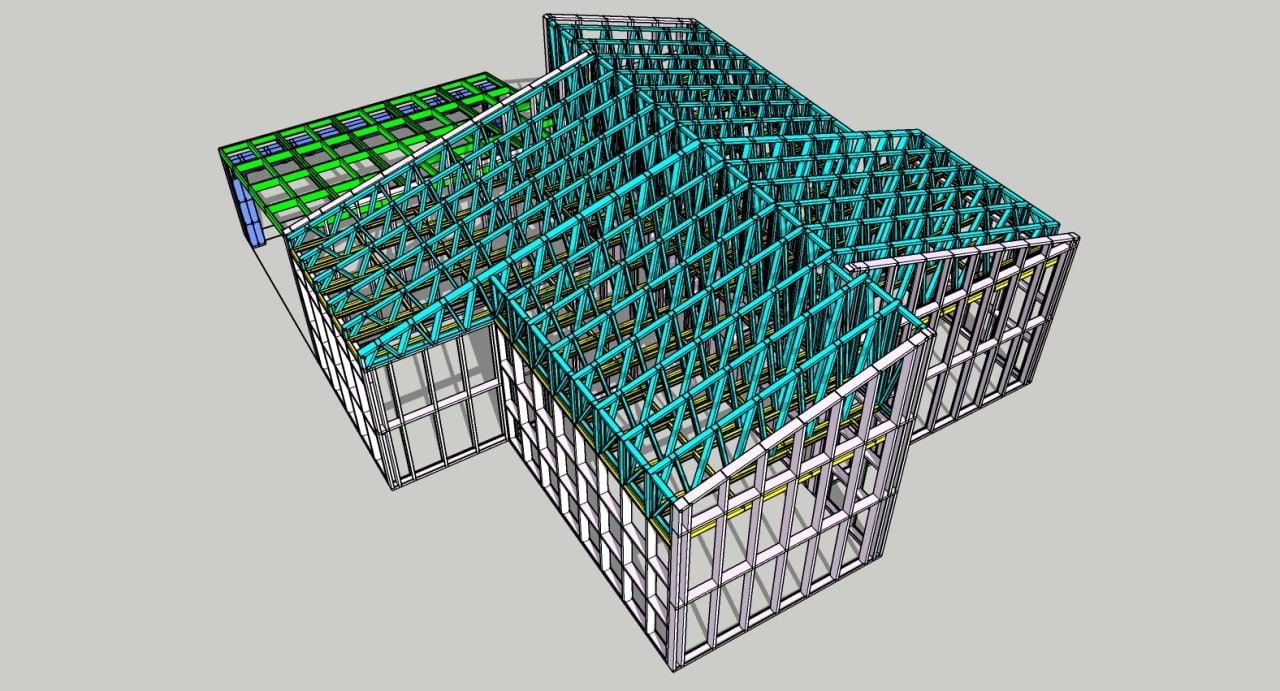

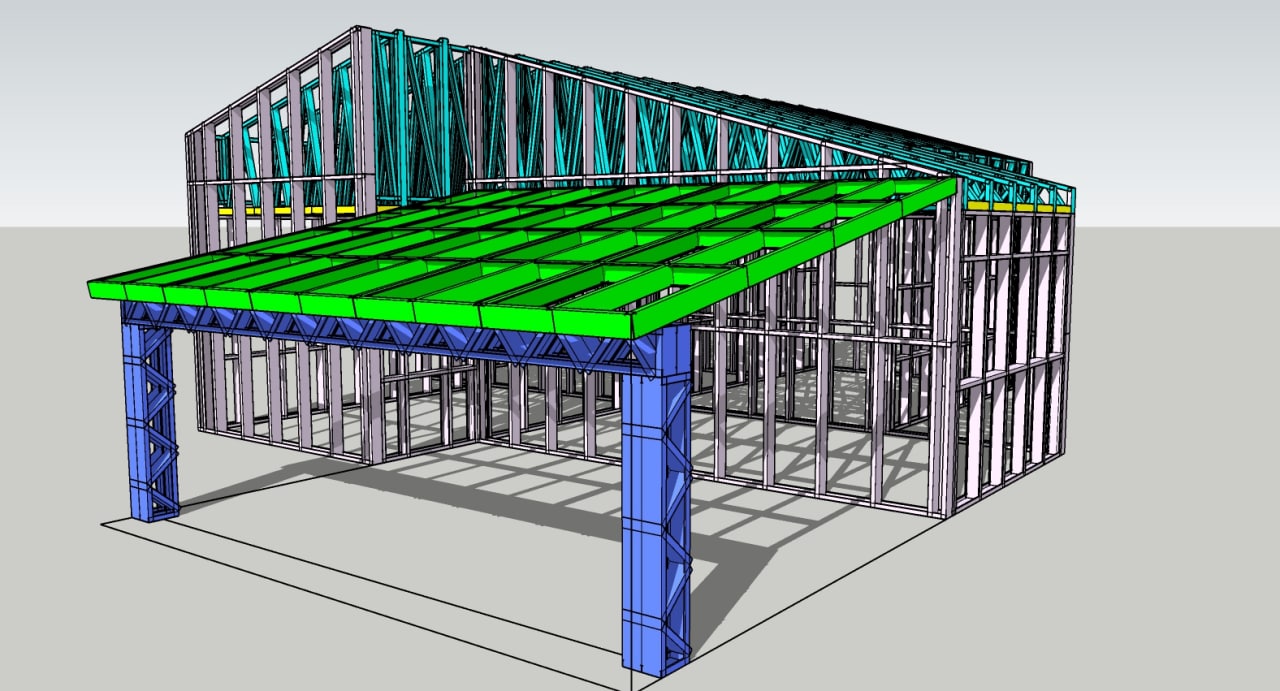

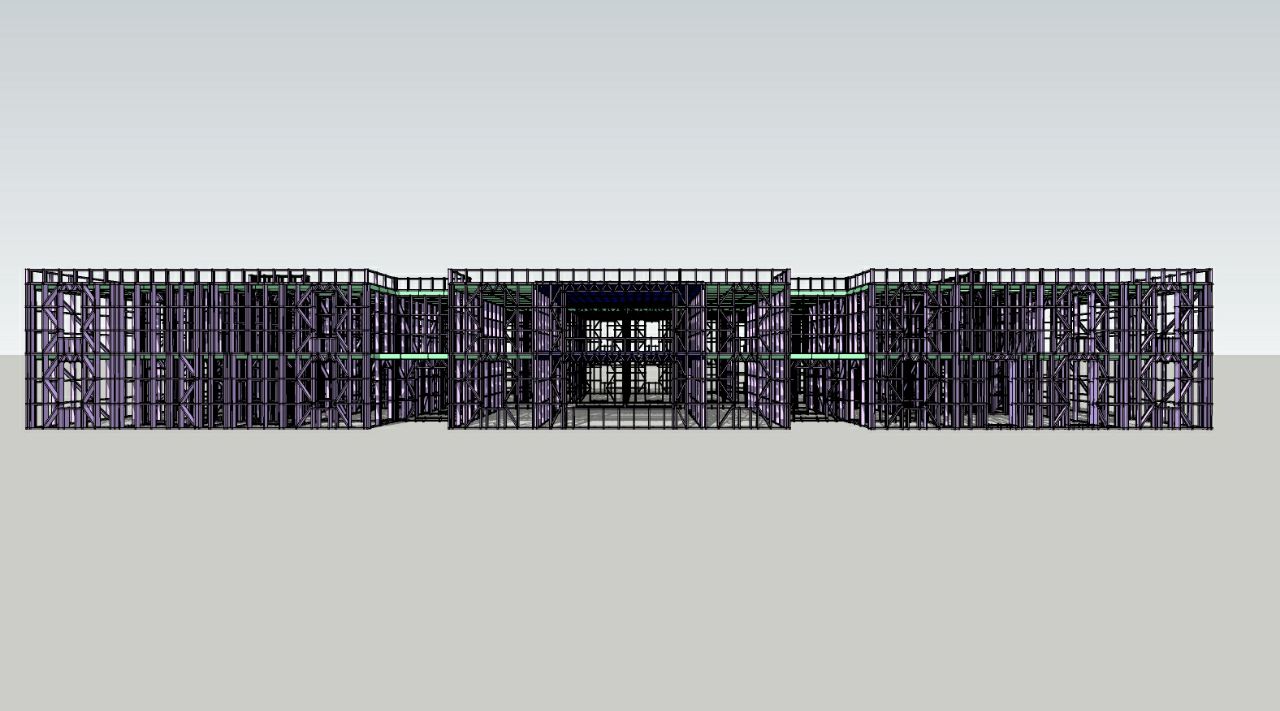

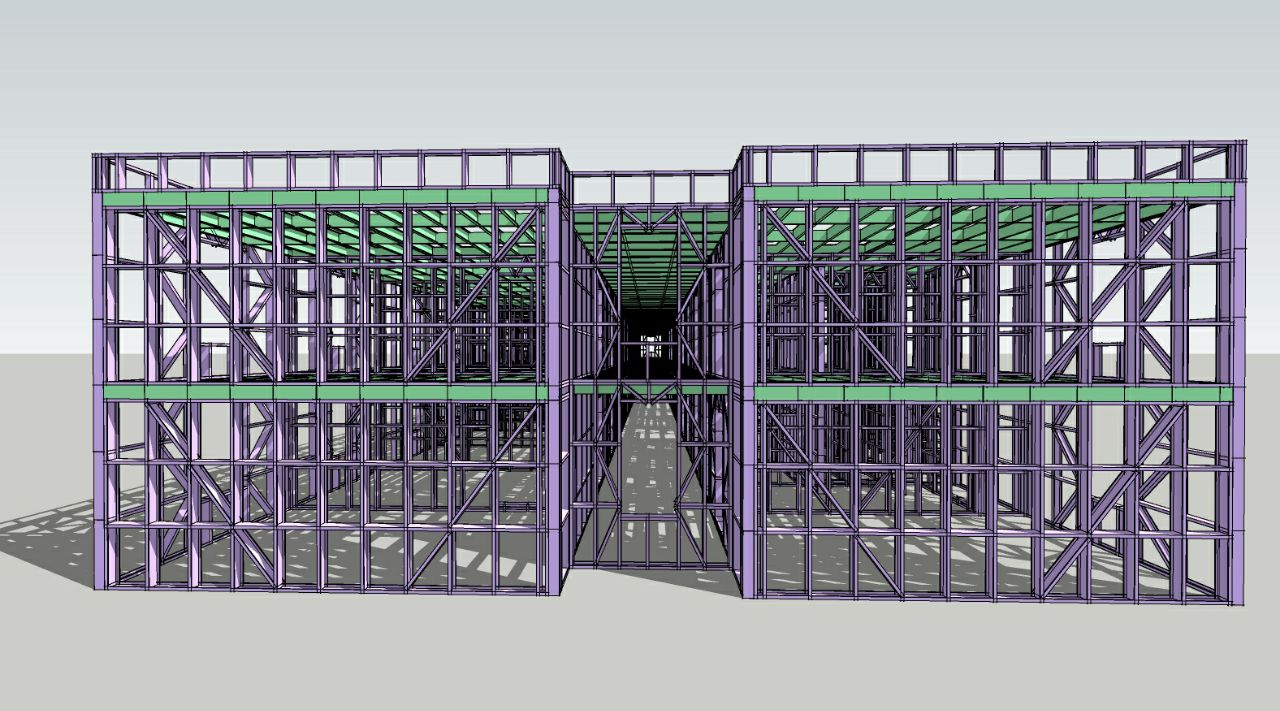

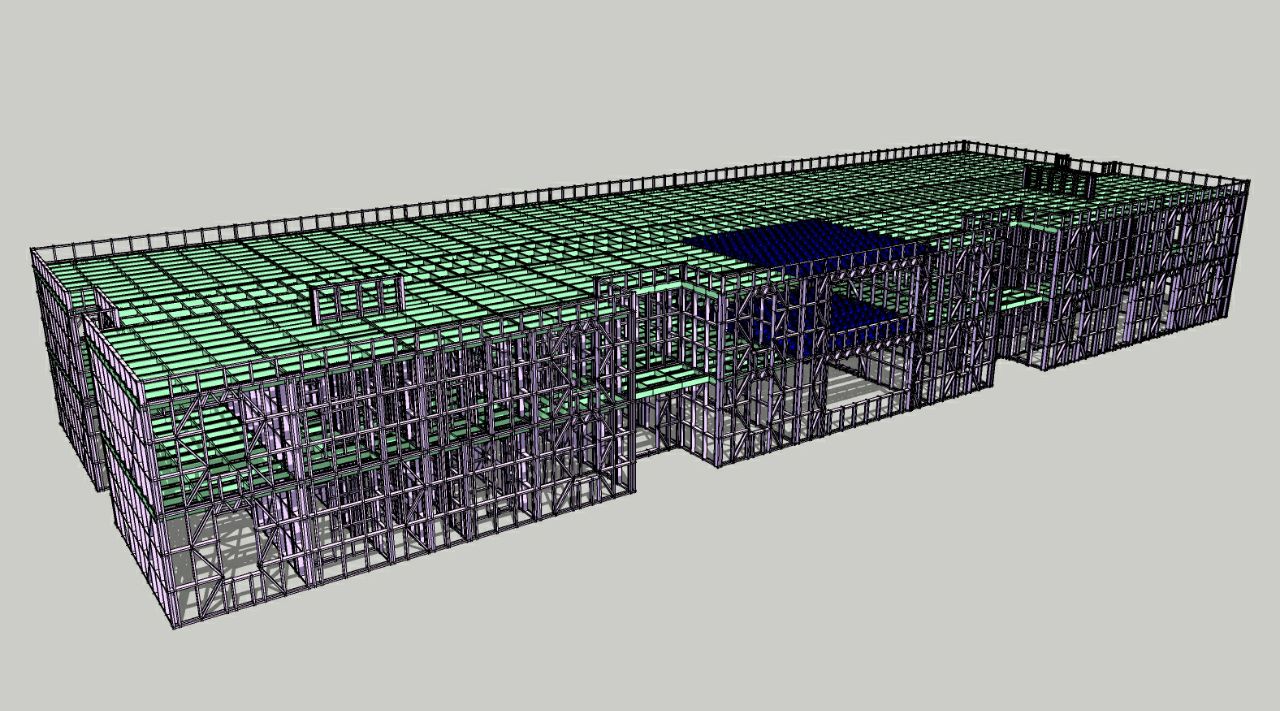

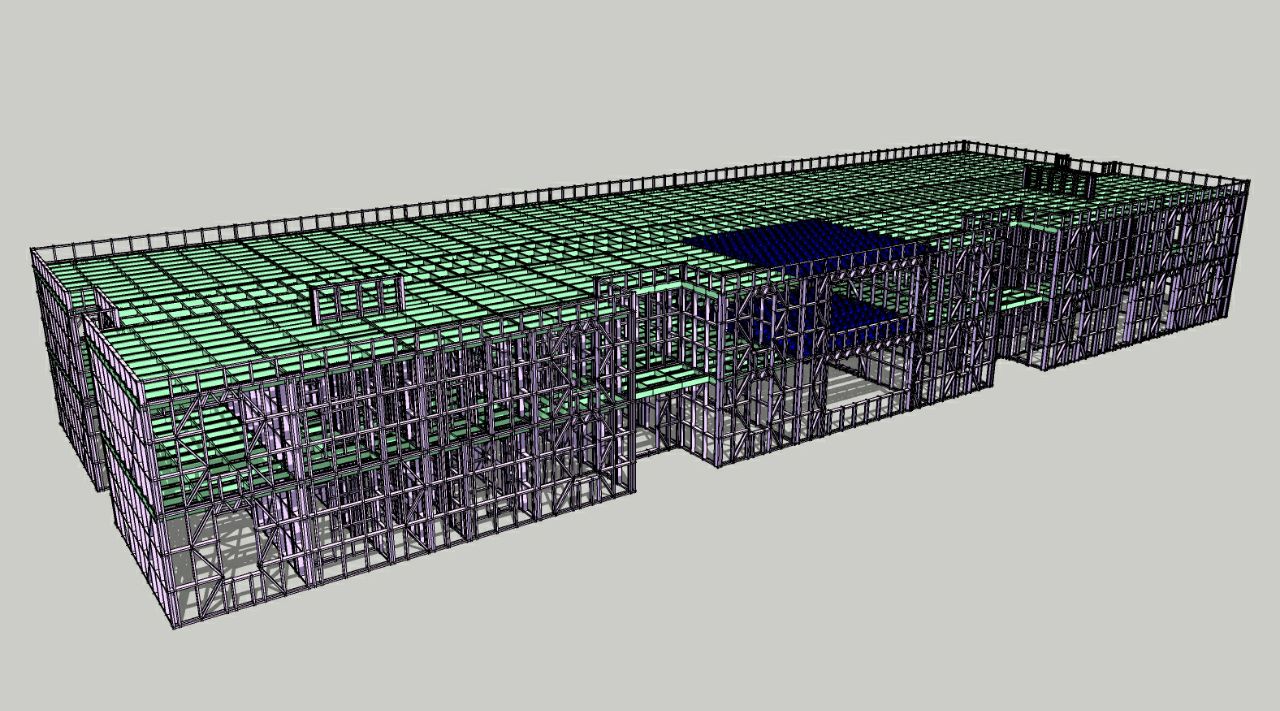

It is not difficult to erect standard and individual premises of any complexity during frame construction. The price of a building made of LSTK depends on the speed of construction, the complexity of the project, finishes, materials that always correspond to environmental friendliness and fire safety. A wide range of materials is united by a common component - the building module. The mandatory elements of the LSTK building are the frame, external and internal finishes, doors and windows.

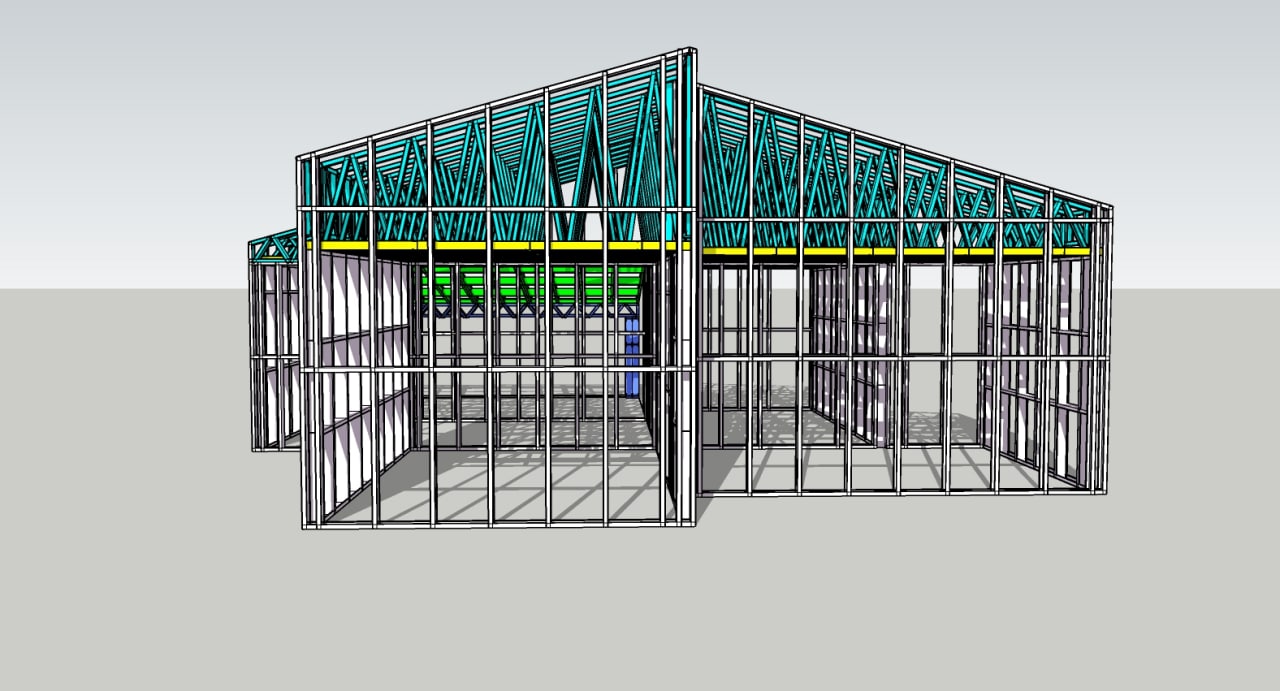

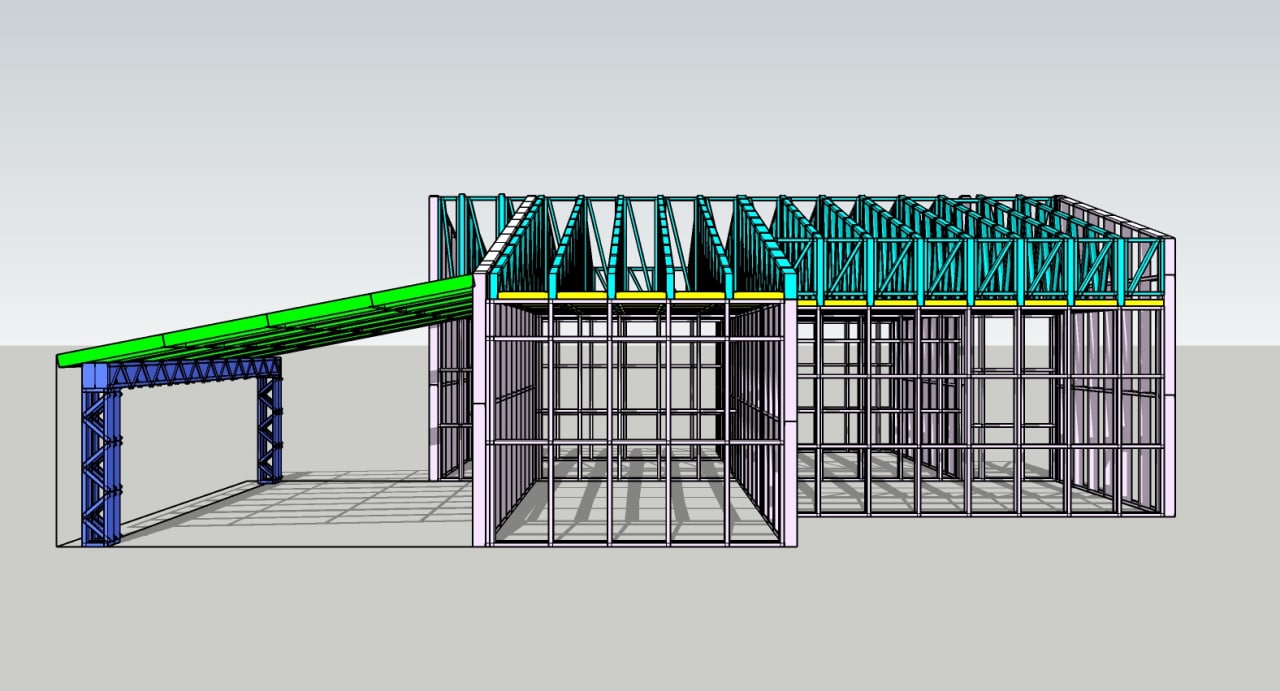

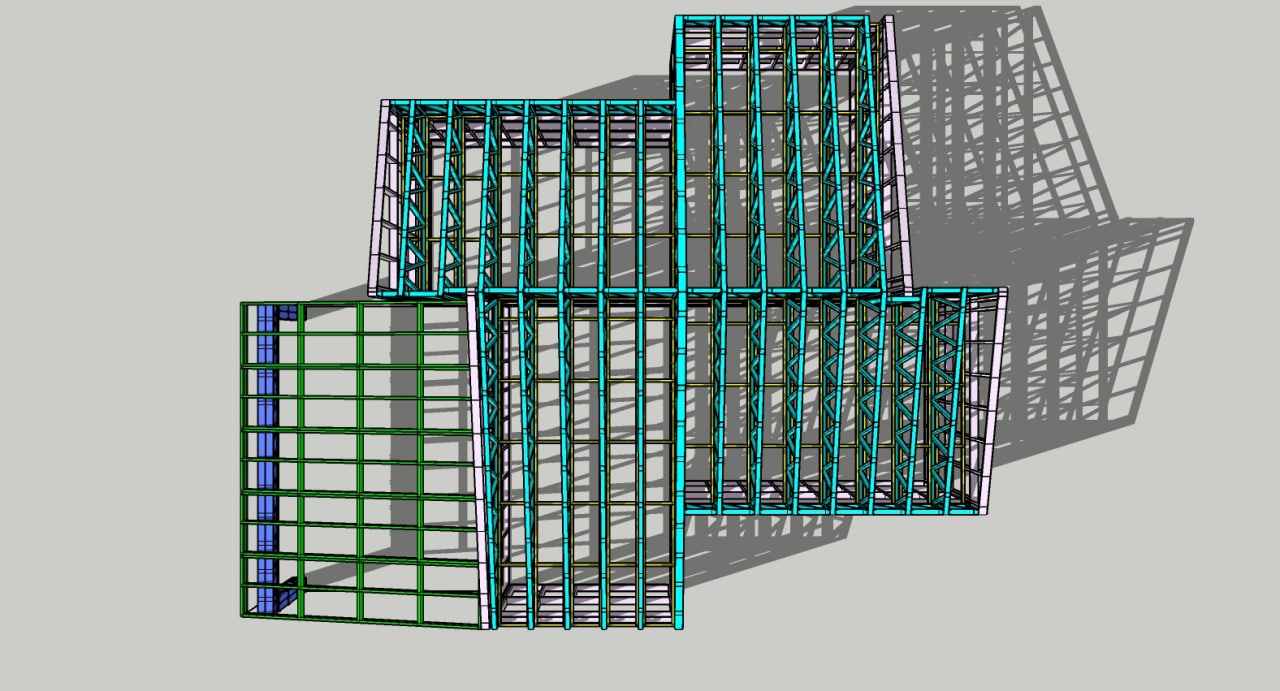

The modern frame of a pre-fabricated building made of LSTK consists of a galvanized steel profile with a thickness of 0.8 to 3 mm, depending on the complexity of the project. Pipes act as stiffeners. The mode of operation of a building made of LSTC directly affects the structure of the main structure. Thus, the use of prefabricated buildings in seismically hazardous areas or areas with significant snow load requires additional fasteners. In addition to galvanizing, the structure is coated with a primer, in some cases painting is carried out. The outer side of the structure and the roof are aluminum composite panels RAL or analogues with the obligatory presence of insulation inside. For fire-hazardous areas, a fire-retardant coating is used on prefabricated buildings. The choice of roof shape (straight or sloped) depends on the design project. Materials for interior decoration are varied and are specified by the customer at the design stage, however, as well as the availability of lighting, water inlet and outlet.

Metal-plastic windows and a metal entrance door from trusted suppliers will make the construction of the LSTK building more reliable. To enhance security measures in multi-storey prefabricated prefabricated buildings, bars are installed on the windows of the first floor. Built-in internal metal or wooden stairs are created taking into account all the wishes of the customer.

Blocks of a prefabricated building, depending on the purpose, can be filled with the necessary furniture and appropriate equipment. For example, plumbing in the bathroom, professional kitchens, ventilation, air conditioning or fire alarm systems.

The terms of production and installation of residential prefabricated modular buildings are amazing: due to high quality standards, production, depending on the volume, takes only 5 days to 2 months, and installation - no more than a week.

Features of installation of modular prefabricated buildings depend on the chosen construction method:

Block-modular method. Block modular buildings are dimensional and standardized, but have the advantage of speed of assembly and installation. The living space already fully assembled at the factory is delivered to the chosen place, the assembly of which took place under appropriate conditions under the supervision of qualified specialists. There is one caveat - this method of installation is possible if there is a specialized transport for the delivery of this structure, which significantly increases the price of a block-modular building. However, the cost of a modular building from LSTK with delivery is still two times lower than a brick counterpart.

Frame-panel method. Frame-and-panel construction provides freedom of action in the size and shape of the product, and also reduces transportation costs. A slight increase in installation time does not cover the advantages of this method. In the last quarter of a century, a metal profile made of low-alloy steel of variable cross section has been used, which increases strength and reduces the weight of the frame by 15-17%. Accuracy during installation of the main unit and additional elements (windows, doors, facades)

The technology for the construction of prefabricated frame buildings from LSTK has long been popular in many countries. It is seen as a logical development of the panel housing boom in Canada, Finland, France, the USA and the USSR. Initially, modular buildings were built only for industrial, commercial and military purposes. However, the growth in demand of private buildings has led to the emergence of modular residential buildings of several varieties and functionality. Due to the strength of the elements, combined with elasticity, a high resistance to seasonal floods, mud flows and earthquakes results. These properties have made such structures popular in difficult areas in terms of soil structure and topography. Today, with the help of LSTK, 90% of structures are built for such purposes as:

commercial and industrial premises;

children's, medical and administrative buildings;

mobile modular buildings for business.

In Ukraine, prefabricated modular buildings are only gaining popularity, especially in the hotel and construction business. During the Soviet period, steel was an inaccessible material, so buying a modular building was only a dream. Now technologies and materials allow to revive the production of modular buildings at an affordable price. Promising areas are modular and not only private kindergartens, mini-offices, mobile car washes, seasonal houses (dacha cooperatives, recreation centers) and warehouse complexes.

Production of modular buildings: materials, terms and features of installation

It is not difficult to erect standard and individual premises of any complexity during frame construction. The price of a building made of LSTK depends on the speed of construction, the complexity of the project, finishes, materials that always correspond to environmental friendliness and fire safety. A wide range of materials is united by a common component - the building module. The mandatory elements of the LSTK building are the frame, external and internal finishes, doors and windows.

The modern frame of a pre-fabricated building made of LSTK consists of a galvanized steel profile with a thickness of 0.8 to 3 mm, depending on the complexity of the project. Pipes act as stiffeners. The mode of operation of a building made of LSTC directly affects the structure of the main structure. Thus, the use of prefabricated buildings in seismically hazardous areas or areas with significant snow load requires additional fasteners. In addition to galvanizing, the structure is coated with a primer, in some cases painting is carried out. The outer side of the structure and the roof are aluminum composite panels RAL or analogues with the obligatory presence of insulation inside. For fire-hazardous areas, a fire-retardant coating is used on prefabricated buildings. The choice of roof shape (straight or sloped) depends on the design project. Materials for interior decoration are varied and are specified by the customer at the design stage, however, as well as the availability of lighting, water inlet and outlet.

Metal-plastic windows and a metal entrance door from trusted suppliers will make the construction of the LSTK building more reliable. To enhance security measures in multi-storey prefabricated prefabricated buildings, bars are installed on the windows of the first floor. Built-in internal metal or wooden stairs are created taking into account all the wishes of the customer.

Blocks of a prefabricated building, depending on the purpose, can be filled with the necessary furniture and appropriate equipment. For example, plumbing in the bathroom, professional kitchens, ventilation, air conditioning or fire alarm systems.

The terms of production and installation of residential prefabricated modular buildings are amazing: due to high quality standards, production, depending on the volume, takes only 5 days to 2 months, and installation - no more than a week.

Features of installation of modular prefabricated buildings depend on the chosen construction method:

Block-modular method. Block modular buildings are dimensional and standardized, but have the advantage of speed of assembly and installation. The living space already fully assembled at the factory is delivered to the chosen place, the assembly of which took place under appropriate conditions under the supervision of qualified specialists. There is one caveat - this method of installation is possible if there is a specialized transport for the delivery of this structure, which significantly increases the price of a block-modular building. However, the cost of a modular building from LSTK with delivery is still two times lower than a brick counterpart.

Frame-panel method. Frame-and-panel construction provides freedom of action in the size and shape of the product, and also reduces transportation costs. A slight increase in installation time does not cover the advantages of this method. In the last quarter of a century, a metal profile made of low-alloy steel of variable cross section has been used, which increases strength and reduces the weight of the frame by 15-17%. Accuracy during installation of the main unit and additional elements (windows, doors, facades)